Example:

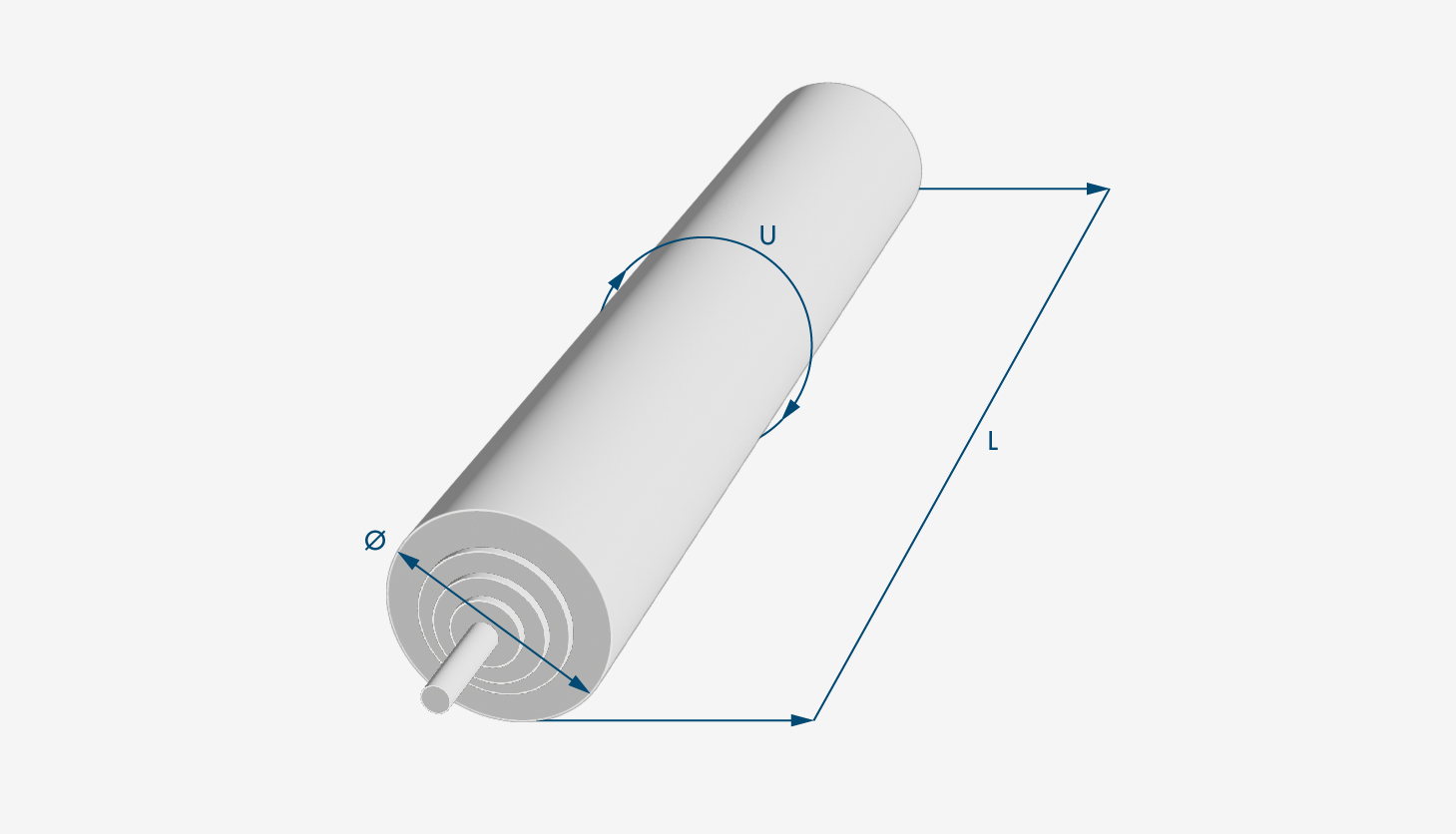

Roller diameter (Ø) 200 mm , roller length (L) 1,500 mm

for a material width of 50 mm

Assembly instructions

How much roller covering is required to cover a roller?

Calculation

= 18,840 mm + 628 mm

for cutting the angle

Result

= 19,468 mm at 50 mm material width

= 14,085 mm at 70 mm material width

= 10,048 mm at 100 mm material width

Basis for calculation

Formula

(circumference = Ø x π)

Winding gaps may be vulnerable points for mechanical damage. We recommend: the smaller the roller diameter, the smaller the material width to make the pitch angle steep as possible.

Which adhesive should I use?

Adhesive manufacturers offer a wide range of products. Read the respective instructions for use carefully. The drying and final drying times must be strictly observed. Please note the following, whether for self-adhesive, wood glue, single-component or two-component adhesives:

For PVC = special PVC adhesive (plasticiser-resistant); for silicone = special silicone adhesive.

Processing recommendation

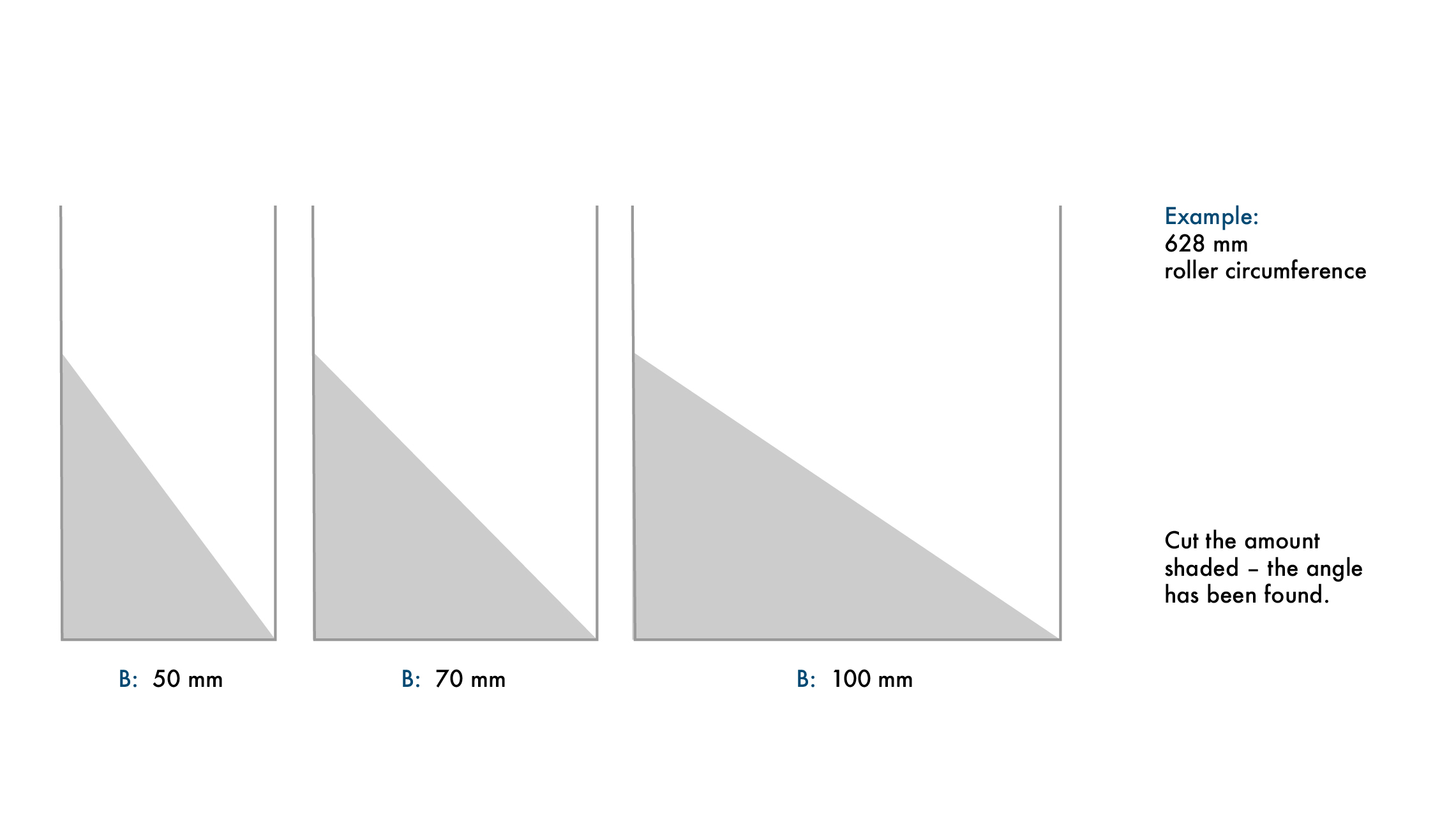

How do I find the right application angle?

You require the roller circumference to obtain the application angle. This is then transferred to the cover as a distance. EXAMPLE: Roller diameter 200 mm = roller circumference 628 mm.

I mark this distance on the beginning of the roller covering as follows:

Note: simplified, not true to scale representation!

Note: simplified, not true to scale representation!