STATE OF THE ART

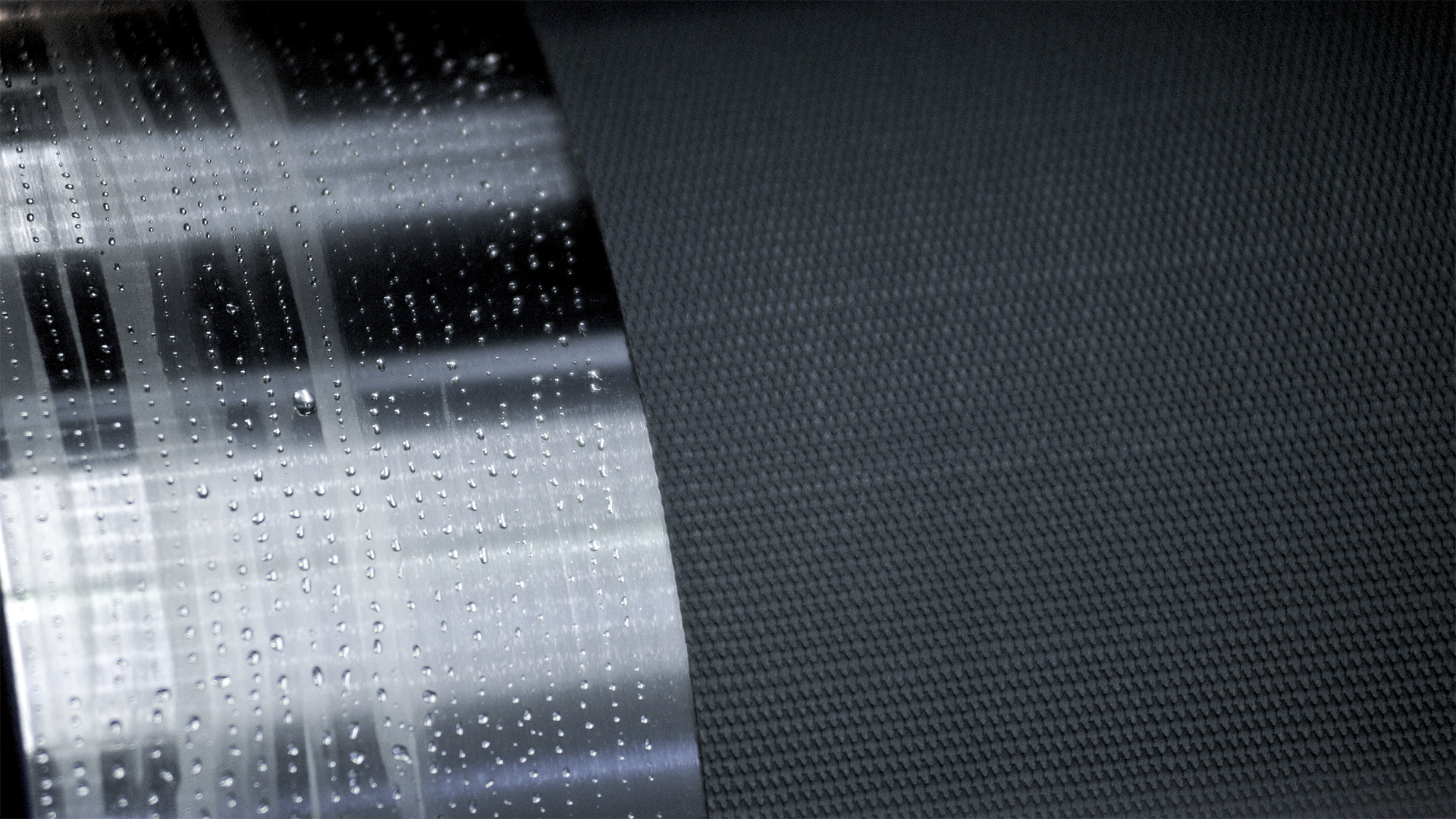

Our expertise as a leader in quality and technology enables us to manufacture our products efficiently and to the highest standards.

Innovation, quality and environmental protection are key components of our production. Our production processes guarantee maximum performance and product quality while also enabling a high degree of flexibility and rapid response times to individual customer requests.

Processes

Reliability is the key to success

The combination of automated processes and craftsmanship enables efficient and cost-effective manufacturing and a high level of individuality and perfection in the end products. Qualified employees ensure optimal quality control throughout the entire production chain.

We have our own weaving machines to create the special fabrics we use and offer. All this ensures that not only do we achieve the highest possible product quality, but that individual customer requirements can be precisely fulfilled and at short notice.

The following materials can be currently processed on BOBOTEX® systems:

Elastomers (natural rubber and synthetic rubber)

Silicones

Thermoplastic elastomers

Thermoplastic polyurethanes

PVC

NBR / PVC

Manufacturing

Concentrated manufacturing expertise on an area of 3,800 m2

We maintain an extensive range of machinery to manufacture our very diverse product range that enables us to produce products from start to finish and guarantees the highest standards of quality.

We currently manufacture on

Automatic vulcanising machine / rotary vulcanising machine (Auma)

Vulcanising press

Extrusion line

Embossing calender with embossing rolls with a wide variety of structures

Tenter frame

Weaving machines for our special fabrics

Environment

We protect our environment

Our production facilities comply with the highest standards of occupational safety and environmental protection. We ensure emission-free production with state-of-the-art process air filter systems: the purified exhaust air from our machines is used to heat our buildings. The resource-efficient use of our energy is very important to us. This is also reflected in our state-of-the-art LED lighting technology throughout the building, where lighting is controlled efficiently and as required using Dali controls. Our energy concept is rounded off by our air heat pump, which makes us independent of fossil fuels.

We also strive to make our products more resource-efficient and sustainable. This is how our Greenline came into being. The base material consists of 100% certified organic cotton and an organic polymer, meaning it is produced from renewable raw materials that can also be reused without leaving any residue, i.e. recycled.